BECK coil nails

High quality and maximum variety

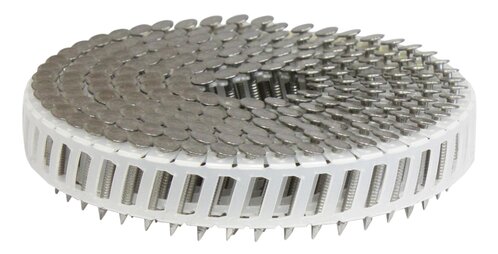

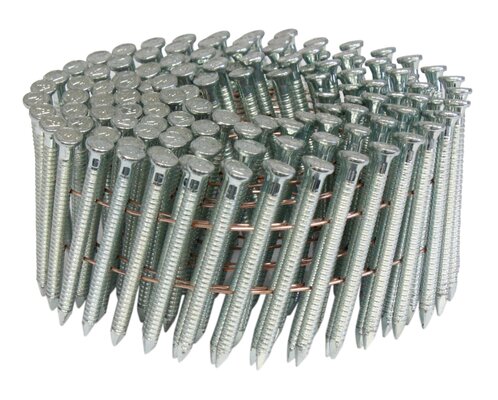

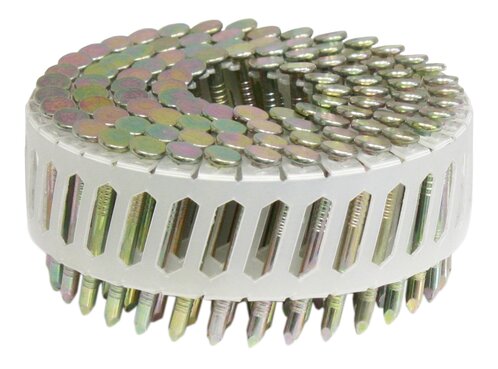

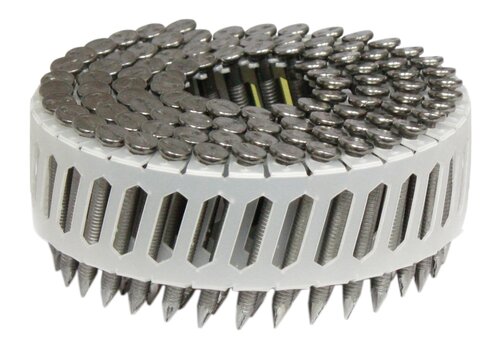

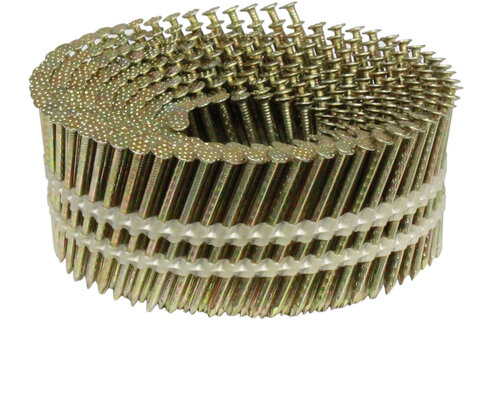

Coil nails are collated nails designed for pneumatic nailers, commonly known as coil nailer (e.g., roofing coil nailer). They are widely used in wood processing, pallet construction, carpentry, and façade construction, where efficiency and strong connections are essential. We offer coil nails in various collation types, including wire and plastic collated coil nails. As a fastening expert and premium manufacturer, we provide a range of materials, along with different tip, head, and shank types tailored for specific applications. Explore our extensive selection of coil nails, including roofing coil nails, coil nails for siding, framing coil nails, anchor nails, and double-headed nails. Beck coil nails are precisely engineered for our own coil nailers and are also compatible with pneumatic nailers from other manufacturers.

BECK coil nails

Areas of application for coil nails: Fastening of roofing felt shingles and bitumen sheets, cladding of façades, fastening of terraces & roof beams, fence construction, fixing of wooden slats in frame construction, wood processing, pallet construction

Coil nails nail points: Diamond point, chisel point, rolled out needle point, angled needle point, blunt point

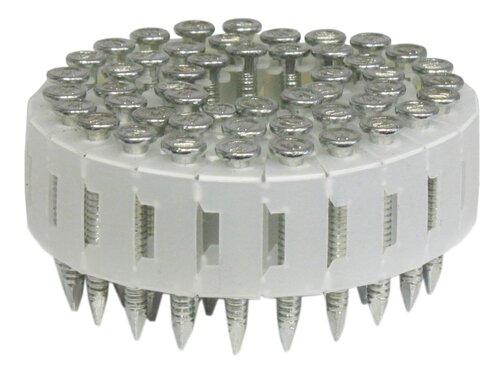

Coil nails head types: anchor head, (countersunk) flat head, double head, lens head, countersunk head, trumpet head, plasterboard trumpet head

Coil nails shank types: smooth, ring, smooth/roughened, screw, twisted, knurled

Coil nails material: standard steel, stainless steel A2, stainless steel A4, high-strength steel, copper, aluminum, brass

Coil nails surface: bright, electro-galvanized, high-strength steel, hot-dip galvanized

FAQ's

- Roofing installations, including asphalt shingles and underlayment

- Framing and structural wood construction

- Fencing and decking

- Pallet and crate manufacturing

- Wall sheathing and exterior siding

- Continuous fastening performance: Enables consistent, rapid-fire nailing in large-scale or repetitive applications.

- Versatile Options: Coil nails are available in various lengths, diameters, and finishes, making them suitable for indoor and outdoor projects, including exposure to moisture or corrosive environments.