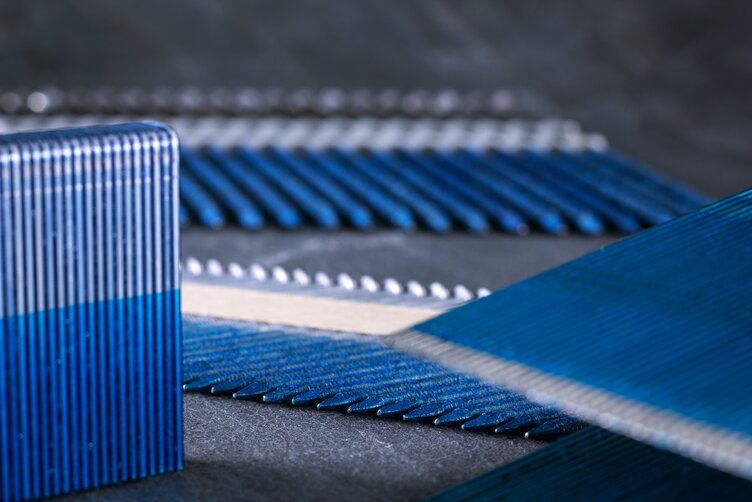

diamond coating for fasteners

The patented coating from BECK for more holding power

More hold - less effort. With our innovative DIAMOND COATING for staples and nails, we put our foot down exactly where you need it. Because we want to develop products that help you improve your performance.

DIAMOND COATING is a special, patented coating for nails and staples of FASCO® fasteners. The coating can be applied to more than 30,000 of our products. As a standard coating, it is offered for SCRAIL® SUBLOC® PRO, JUMBO strip nails, fence staples & copper clad staples for utility poles. The proprietary coating composition ensures that friction between the fastener and the wood structure is reduced.

Benefits of Diamond Coating

- Possibility to switch to lighter or smaller tools

- Ideal combination with tools with lower power

- Less strain on the wrists

- Less tool wear

- Easier penetration in hard-drive applications, such as harder wood, reclaimed wood, frozen wood

- Maximum performance in difficult applications

- Possibility to switch to shorter nails

Nails with or without DIAMOND COATING? A comparison shows the difference.

"Beck is an innovative and flexible company that responds individually to our customers' wishes and always delivers goods of a very high quality. To be able to hold one's own in today's market, one needs innovative products with high quality. In this respect, BECK has proven to be a strong partner at our side."

faqS

The maximum pull-out force is given immediately after the driving-in process.

The patented formula ensures that the resin remains on the shaft and does not rub off on the surface of the element to be fastened when it is being driven in.

Wherever particularly high pull-out values are required, where you have to shoot into frozen or very hard wood or when you have to work with less air pressure or when the power of the tool is not sufficient for driving it in completely.