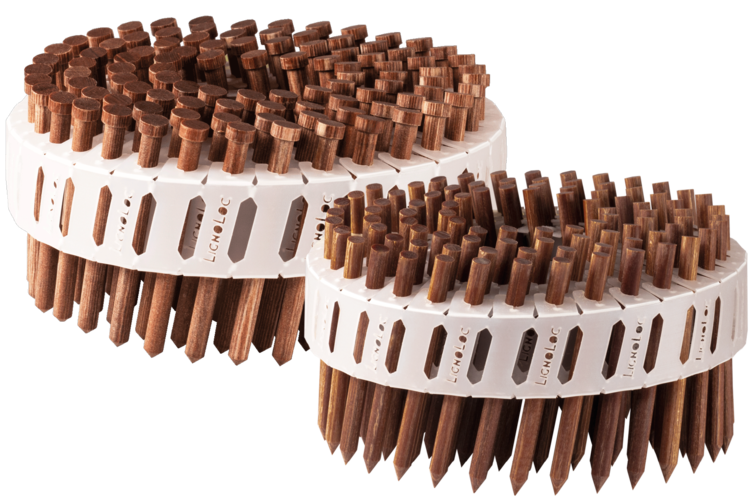

CIRCULAR TIMBER CONSTRUCTION WITH LIGNOLOC® WOODEN NAILS

Metal-free wood-to-wood connections for circular deconstruction, easy recycling, and timber components that can be cleanly reused.

Imagine this: a building does not have to be demolished, but can be used as material banks – carefully deconstructed layer by layer. Walls, ceilings, and entire modules leave the construction site not as demolition waste, but as pure, single-material resources ready for their next use.

Deconstruction begins with the choice of a sustainable fastener

At the moment of completion, hardly anyone thinks about deconstruction. Yet this is precisely when it is determined whether a building can later be returned to the material cycle or must be disposed of at high cost. Sustainable buildings must be capable of being reintegrated into energy and material cycles at the end of their life cycle. Deconstruction descriptions therefore document how components can be dismantled without damage, separated for reuse, and disposed of or reused as mono-material elements. What matters most are not only the building materials themselves, but above all the way they are connected:

- How are materials with different service lives connected to each other?

- Can layers and components be separated without damaging adjacent layers?

- Do the resulting material streams remain mono-material – or do they become hard-to-recycle composites?

Screws, metal nails and adhesives quickly turn timber constructions into complex composite systems whose deconstruction becomes laborious, expensive, or even impossible. LIGNOLOC® addresses this challenge directly at the fastening point – turning the connection into an active design decision for truly circular construction.

Fasteners: from a hidden problem to a lever for circular timber construction – that’s what LIGNOLOC® by BECK makes possible.

Design for Disassembly: buildings as planned material reservoirs

Design for Disassembly (DfD) means considering from the very first draft how a building can later be dismantled into components and materials with clear pathways for reuse and recycling. LIGNOLOC® wooden nails support this principle because the connection itself is designed for circularity. Timber frame, CLT, NLT and timber block constructions using LIGNOLOC® can be documented as mono-material timber components, integrated into material passports and BIM models, and later deconstructed in a targeted manner.

- Simplified deconstruction descriptions – load-bearing and non-load-bearing elements can be classified as mono-material, recyclable timber components and clearly assigned within the DfD concept.

- Improved certification potential – metal- and adhesive-free constructions directly support criteria related to disassembly, recyclability and resource conservation.

- More end-of-life options – components become material banks: reuse, upcycle, or recycle them materially instead of disposing of them.

- Preservation of embodied energy – reusable timber modules retain their embodied energy rather than being discarded as mixed construction waste.

Even today, architects and planners deliberately use LIGNOLOC® to design buildings as future material resources – from multi-storey timber housing to demountable office buildings and temporary beach pavilions. Discover reference projects in which deconstructability, reuse and recyclability were decisive factors for choosing LIGNOLOC®.

FAQ

Yes. Because LIGNOLOC® wooden nails are made entirely of wood and create a cohesive bond when driven in, CLT and other mass timber elements can be machined, shredded or further processed without any additional sorting. The nails behave like the surrounding wood, do not damage tools or machinery, and support clean material separation. This reduces disposal costs and significantly improves recyclability — a key advantage for truly circular timber construction.

Yes. LIGNOLOC® wooden nails hold European Technical Assessments (ETA), making them approved for load-bearing and structurally relevant timber connections in Europe. They also carry an IAPMO certification for the North American market, confirming their suitability for use in load-bearing timber elements.

The nails can be used in wall, floor and other structural components and meet all requirements for load capacity, withdrawal resistance and long-term performance.

Upon request, we can provide all necessary documentation, structural calculations and project-specific recommendations to help you integrate LIGNOLOC® optimally into your design.

LIGNOLOC® wooden nails enable pure wood constructions without any metal fasteners. This eliminates complex separation processes or the need for specialised recycling pathways. All components can be clearly classified as wood, reducing documentation effort, simplifying compliance verification, and increasing transparency throughout the entire building lifecycle — a major benefit in circular timber construction.

LIGNOLOC® has a proven positive impact on the sustainability performance of a building project. By eliminating metal fasteners, the carbon footprint of the fastening system can be reduced by up to 66%, supporting stronger results in certification schemes such as DGNB, LEED or BREEAM.

In addition, material-pure wooden connections enhance the dismantling and reuse potential of timber components — a key factor in circular construction and in life-cycle cost assessment.

From single-family homes to serial modular construction: with wooden nails, you can design timber structures that are built efficiently today and can be deconstructed as mono-material components tomorrow. No metal, no adhesives – with clear material streams for reuse and recycling.